CATALOGUE

The production process in the creation of electrical cables is taken care of in each phase: the quality of the single coil and single coil are ensured not only by the certifications obtained by the company but by the specialization of the members of the production team, appropriately selected and trained in the field.

PRODUCTIVE PROCESS

Thanks to the appropriate machinery, guided as always by the skilled hands of our employees, the production process begins in compliance with the regulations in force certified by the notified bodies:

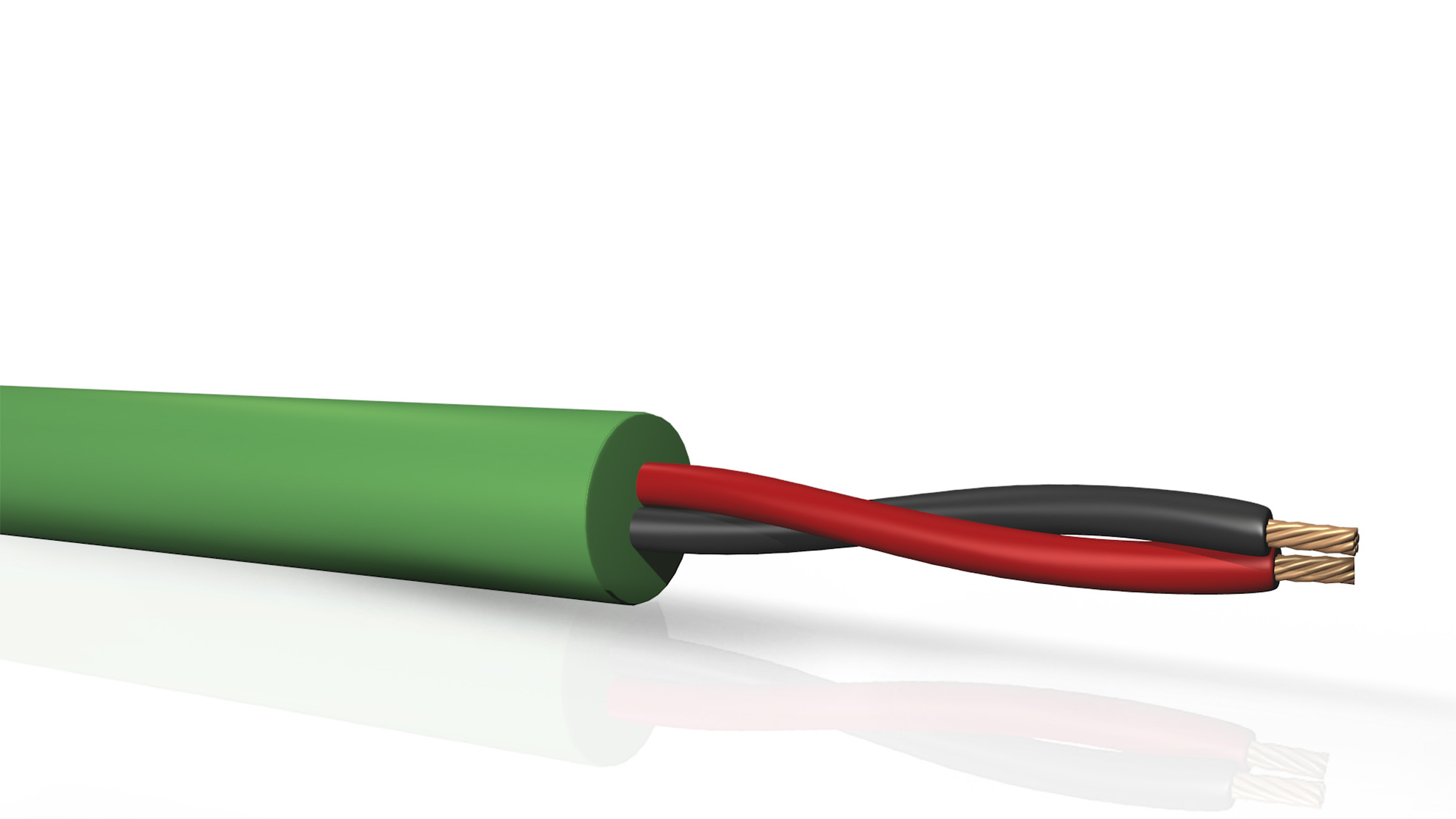

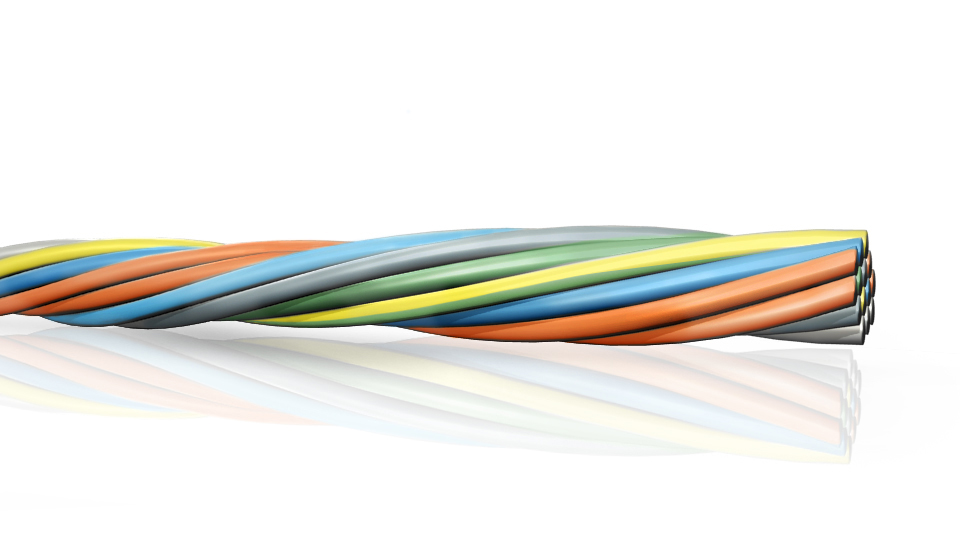

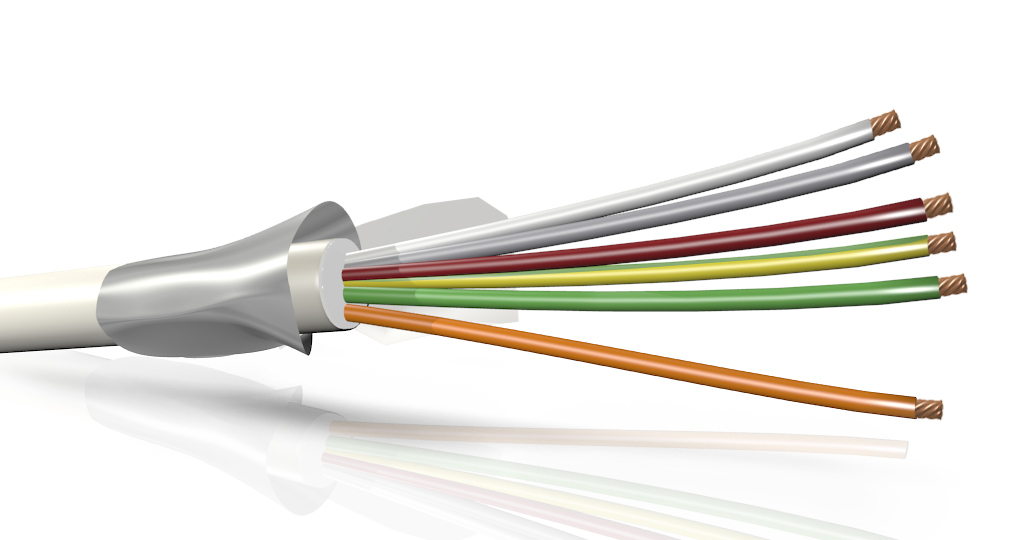

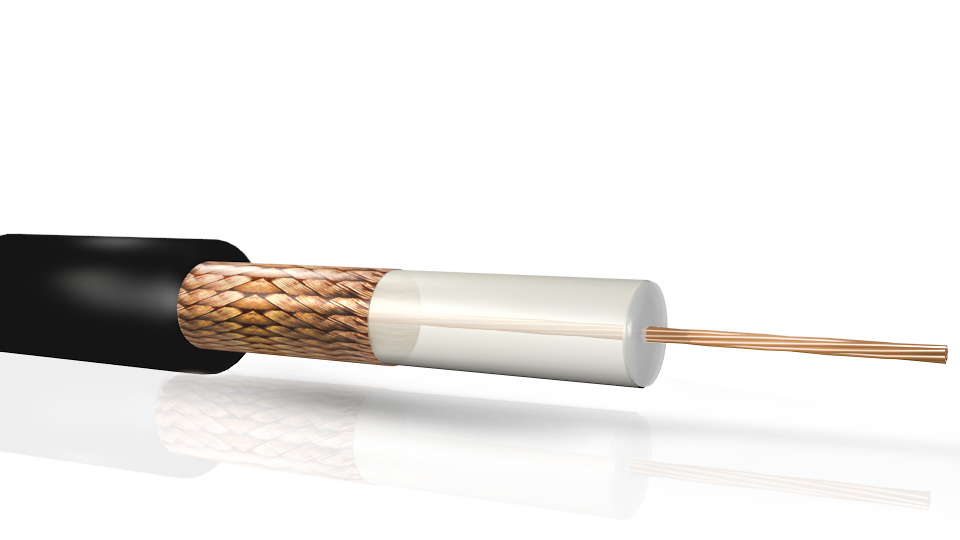

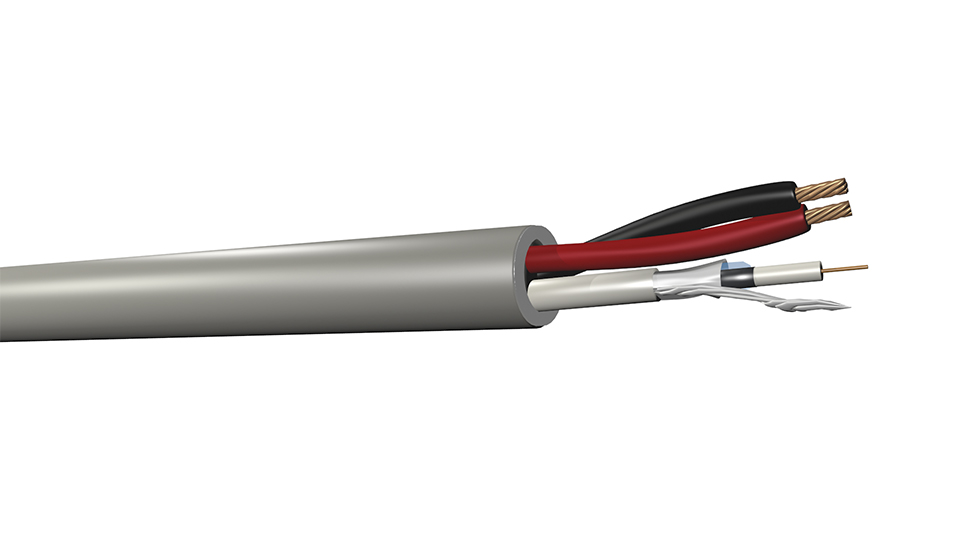

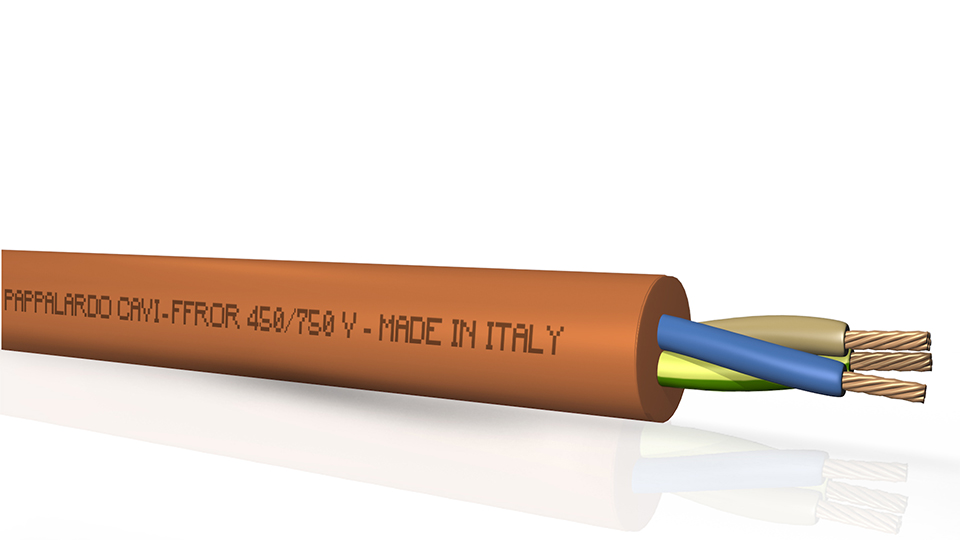

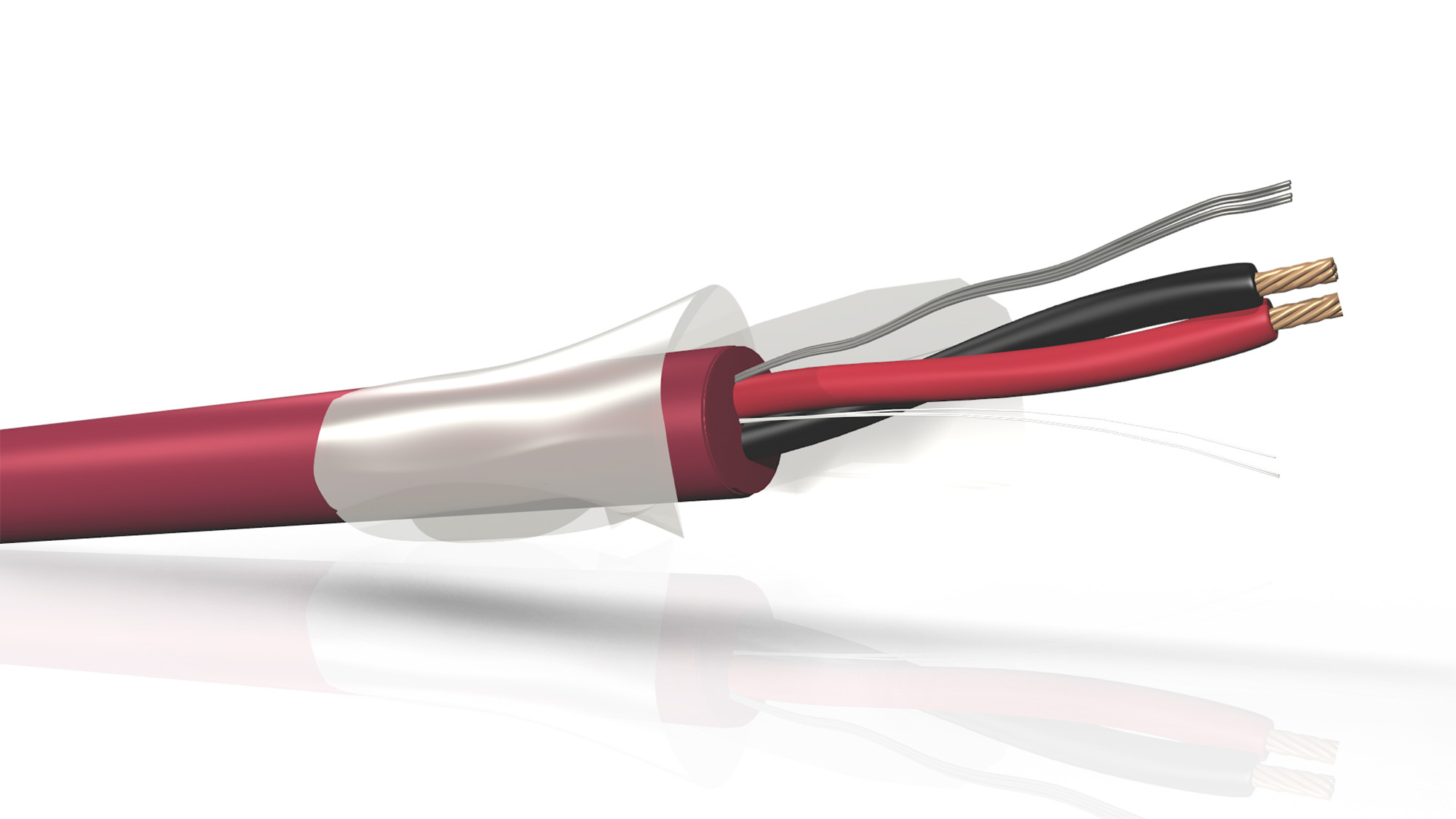

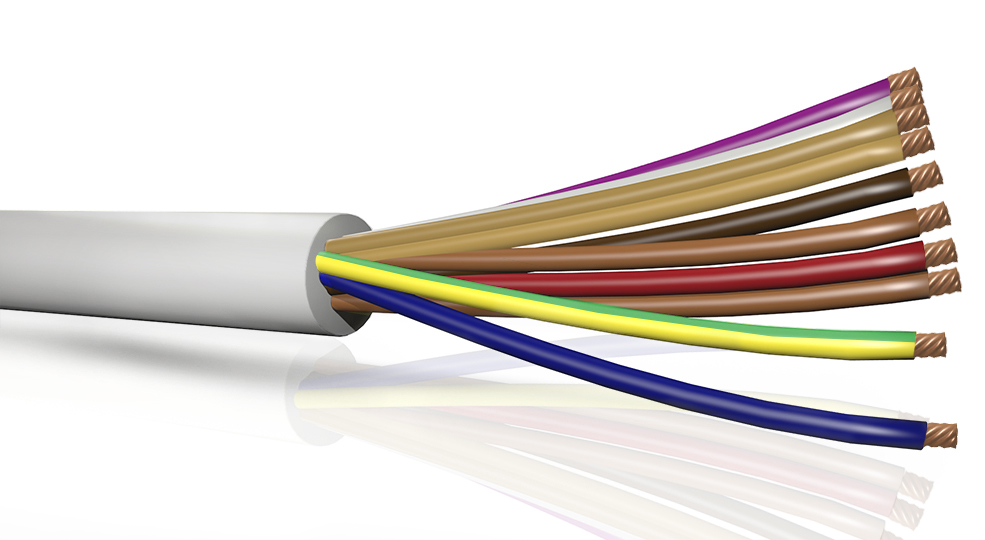

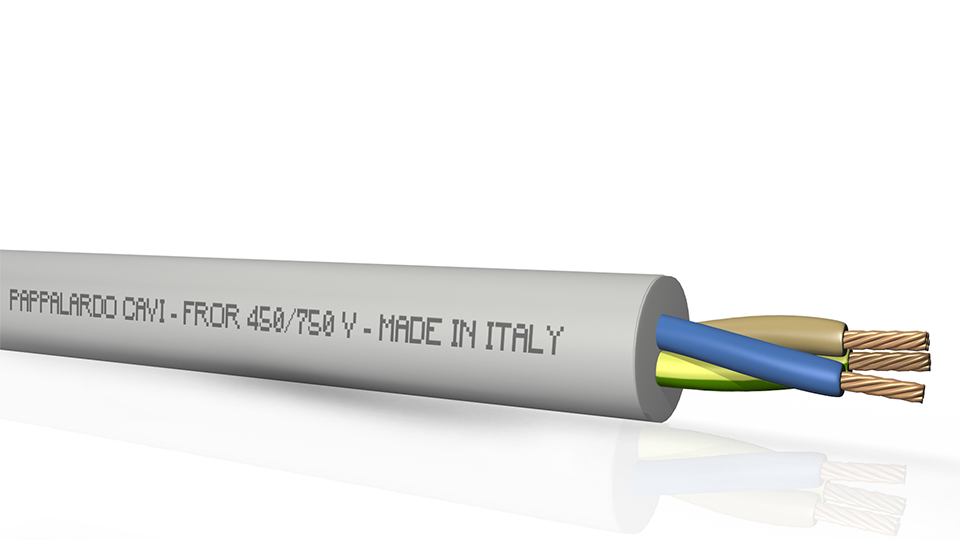

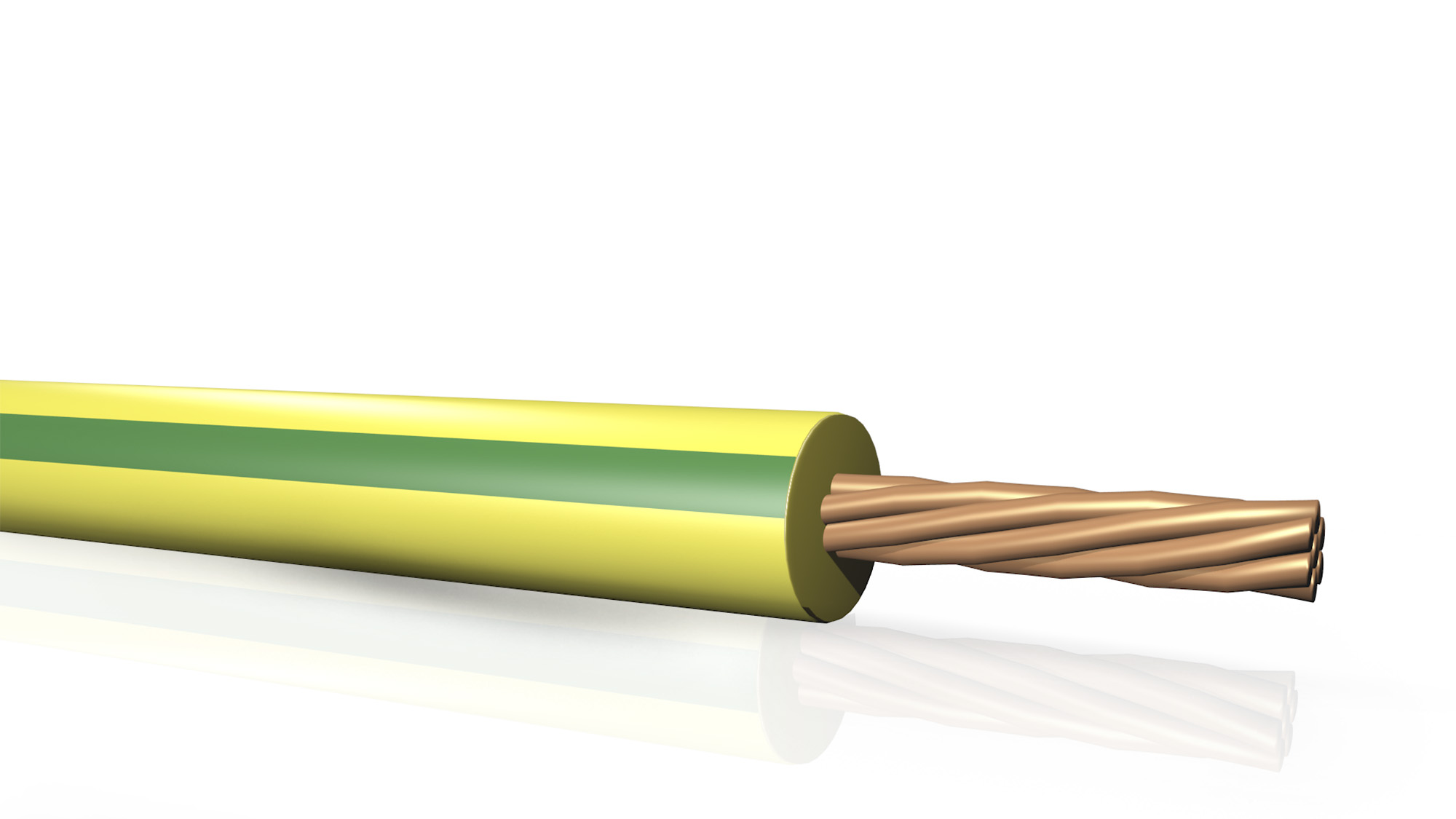

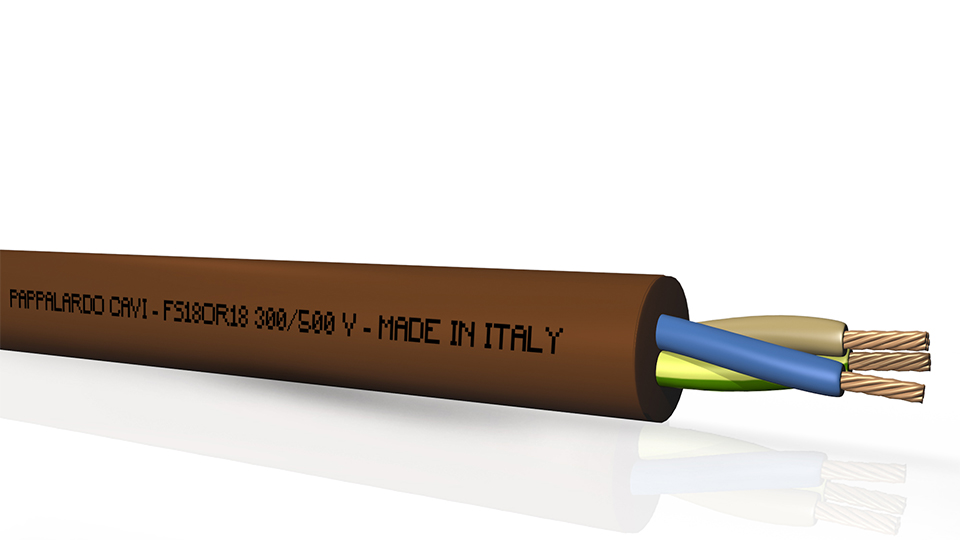

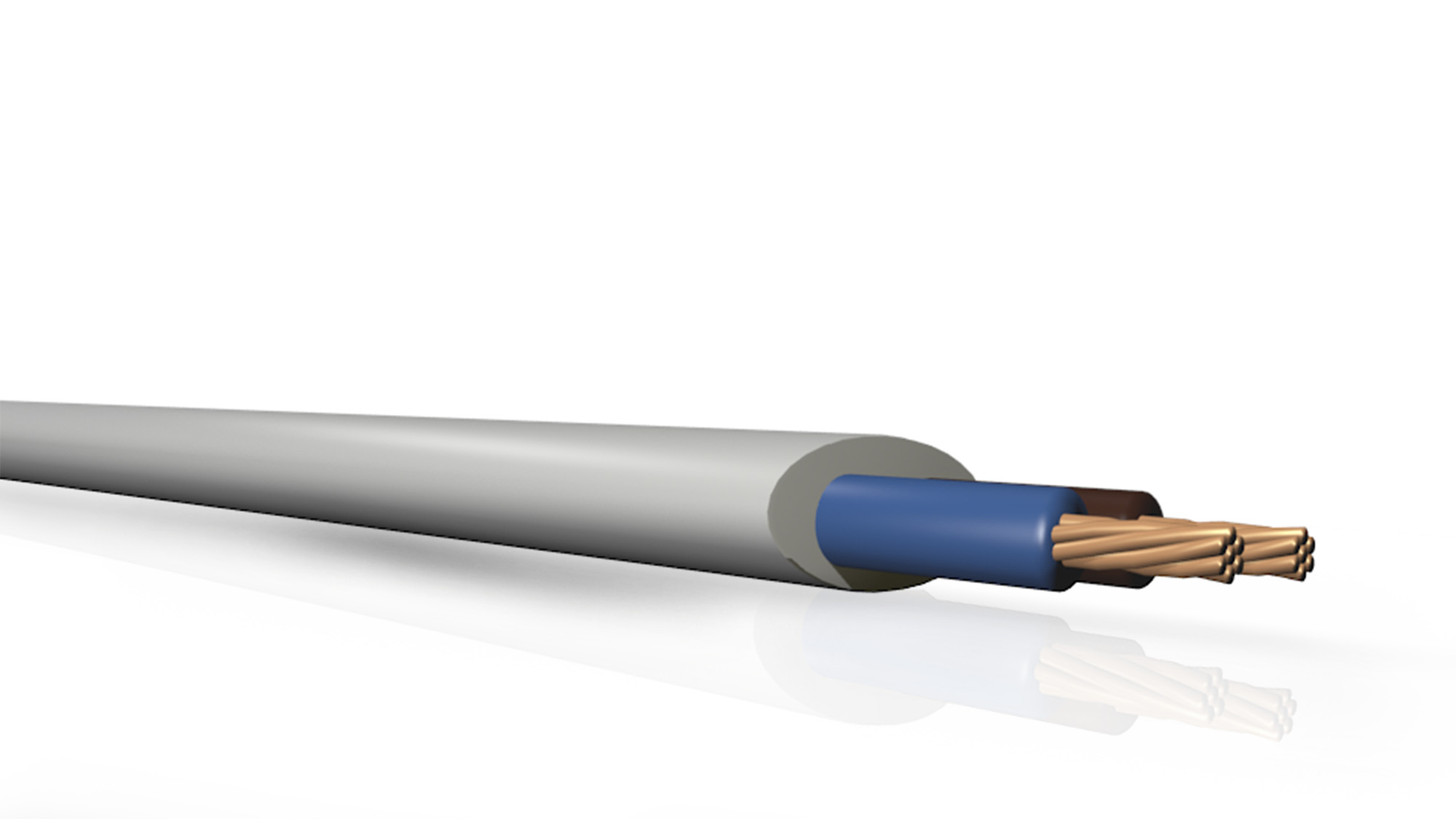

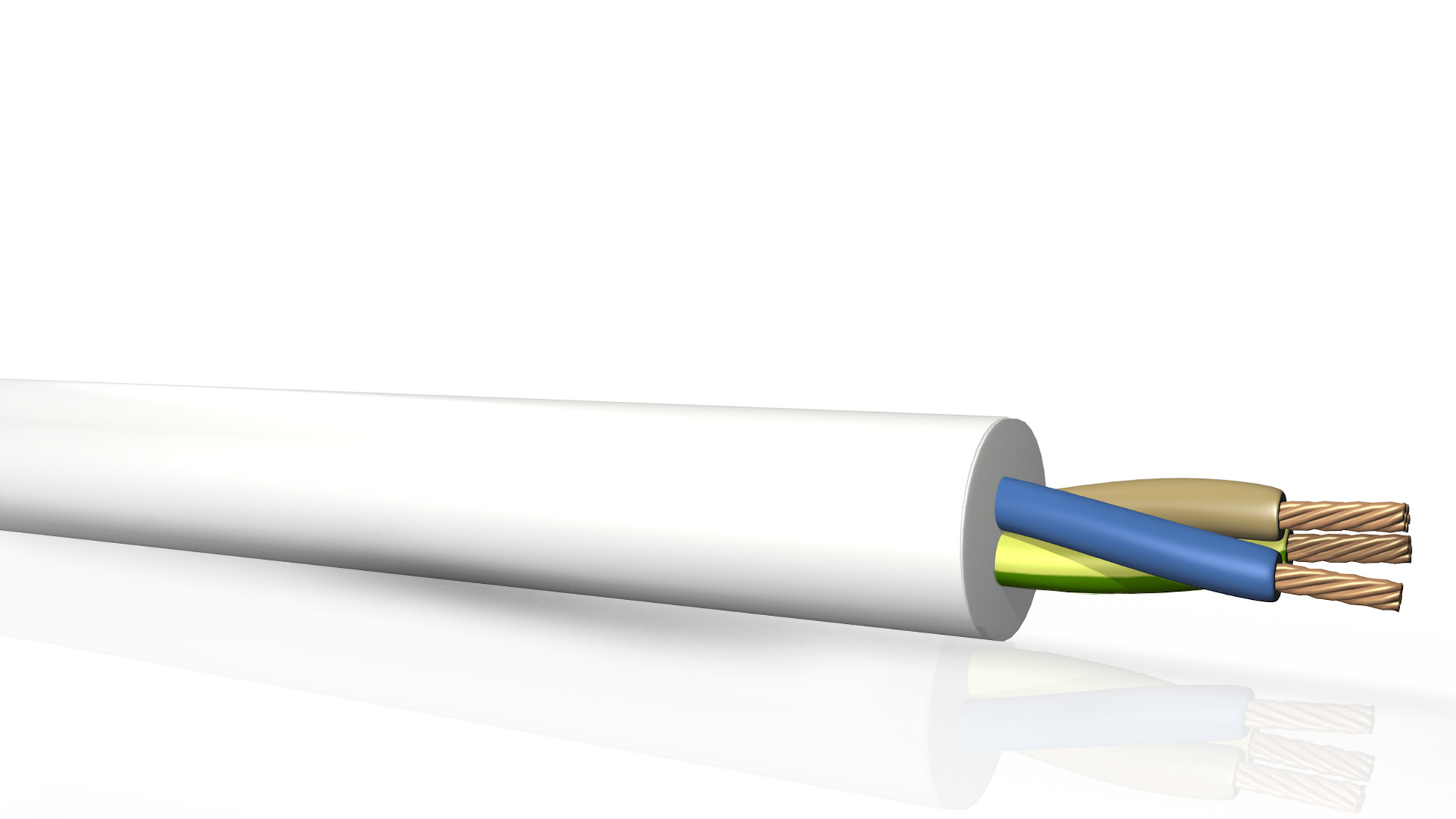

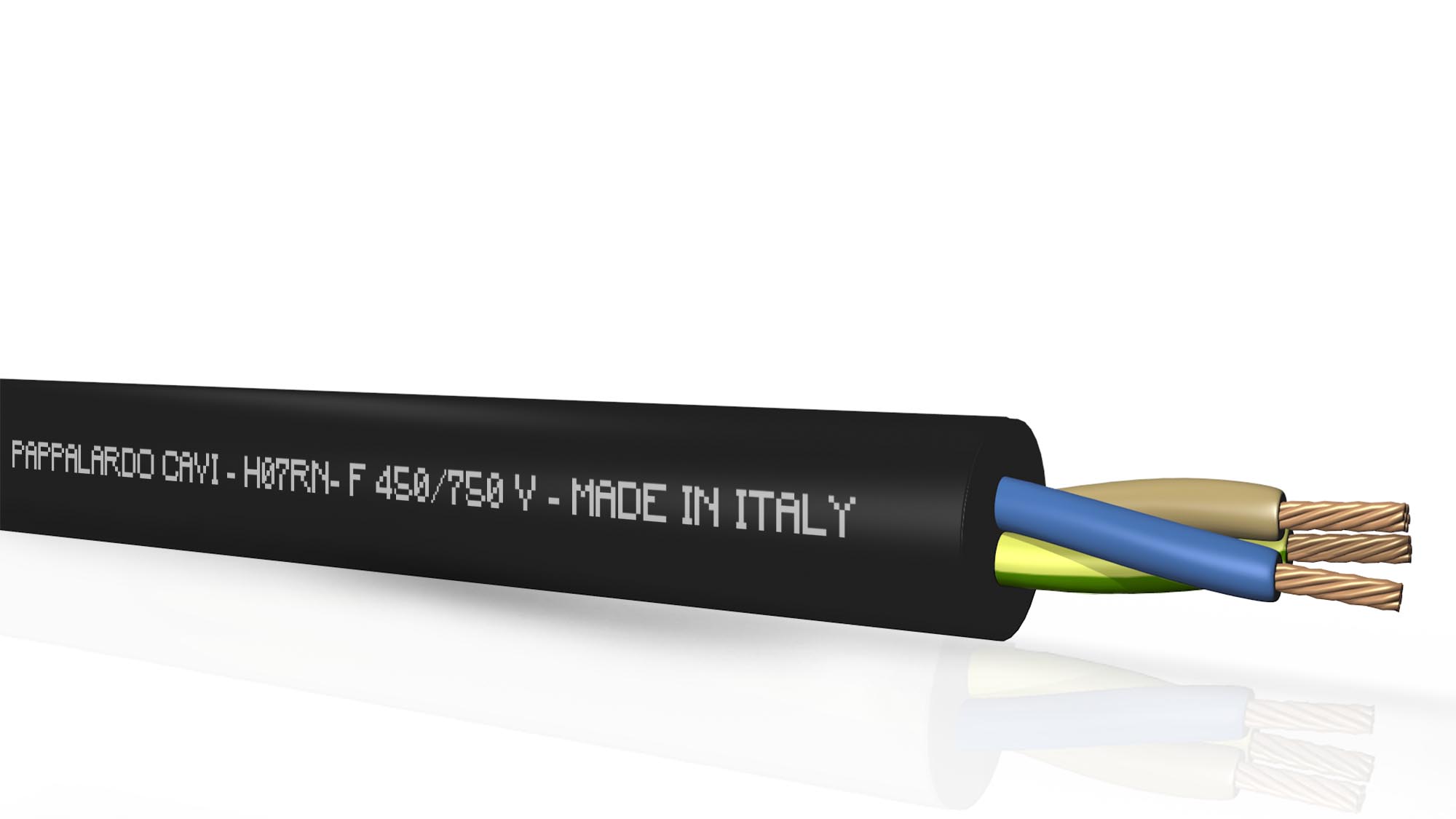

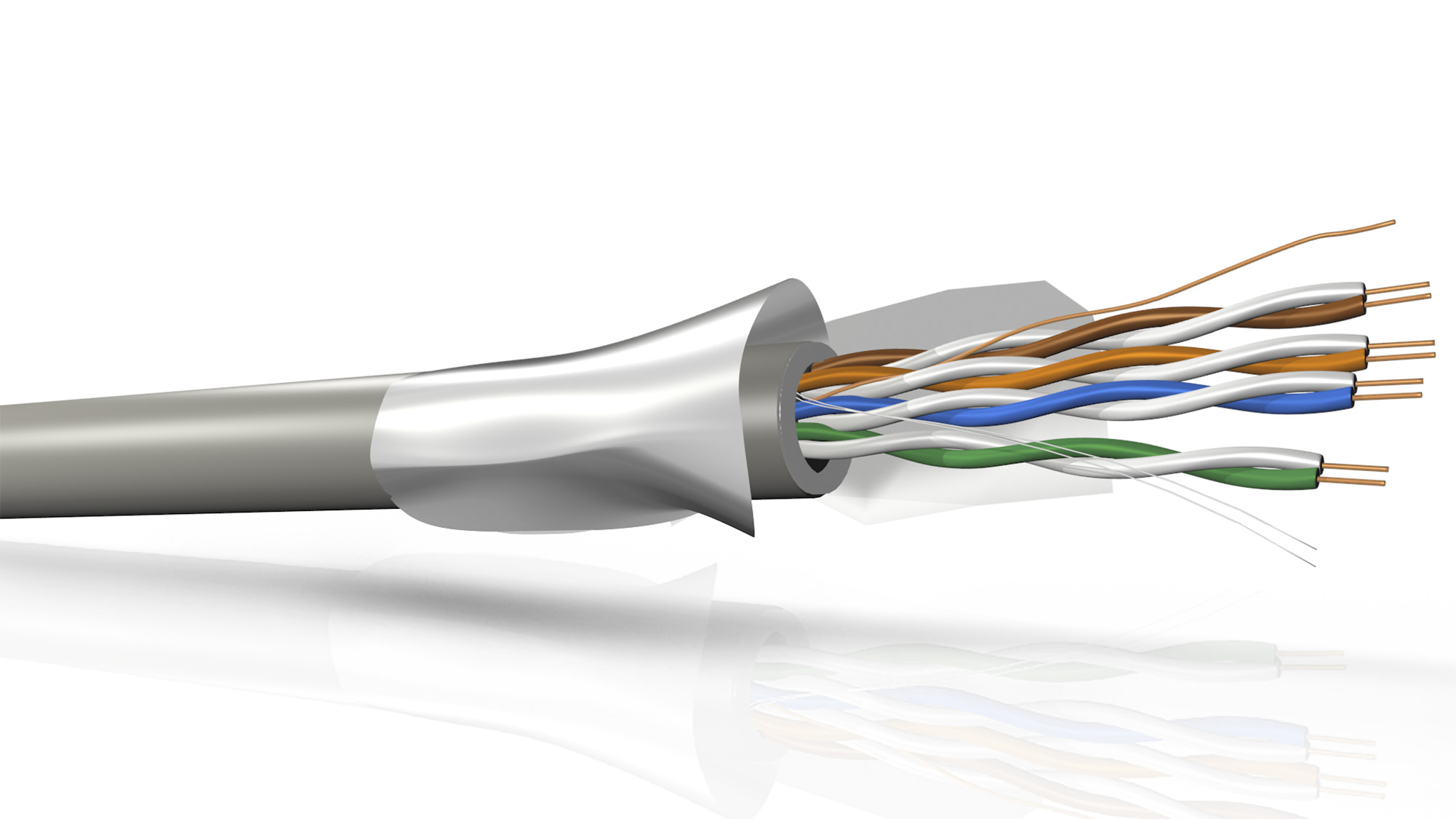

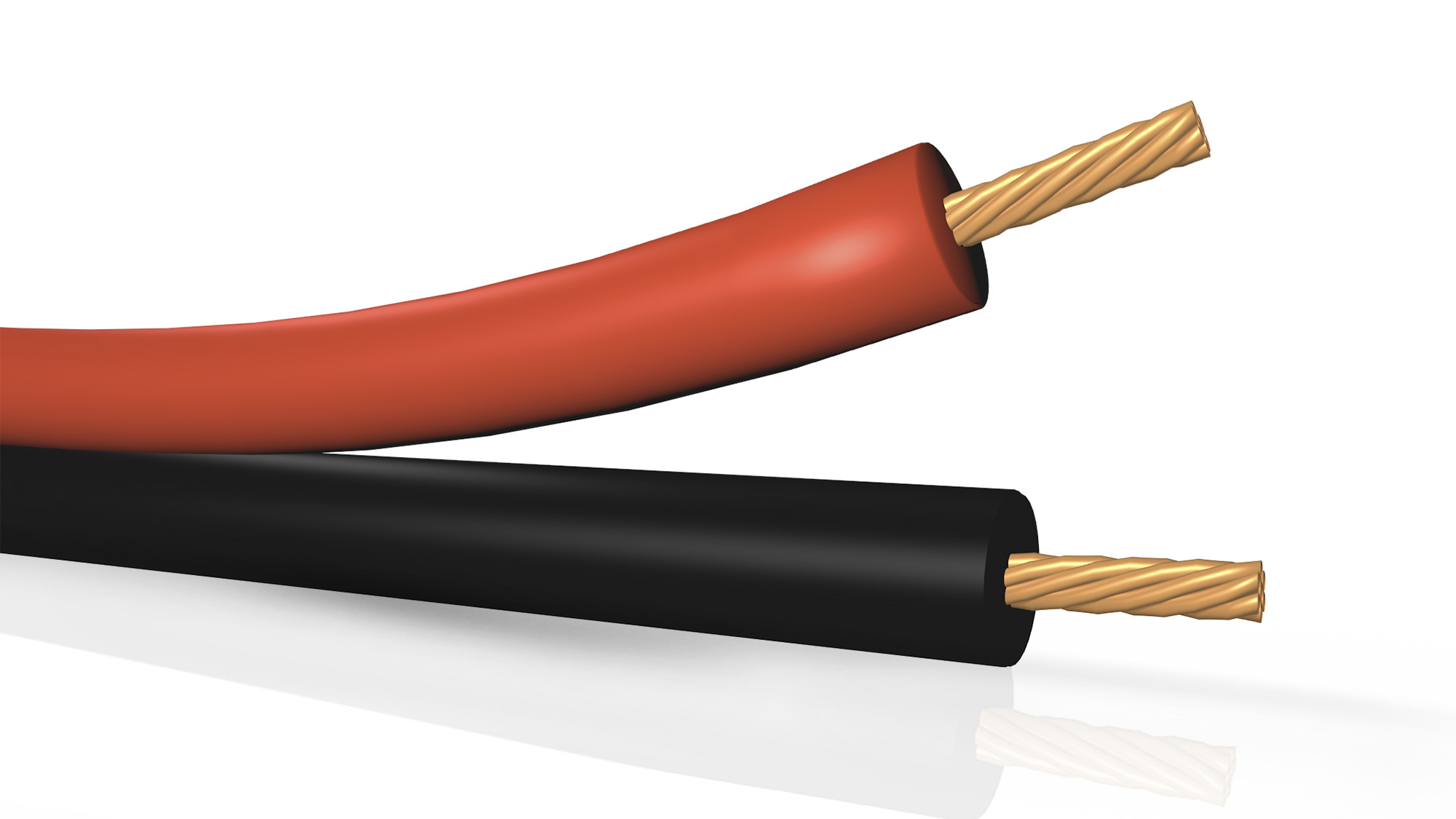

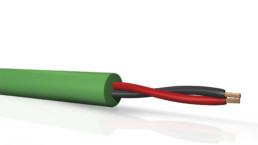

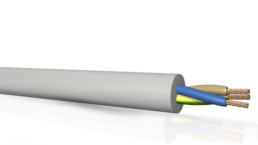

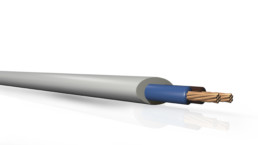

THE STRING of our raw material the “copper”. Subsequently, the COATING of the stranded copper takes place using specific materials with differentiation of colors according to the use for which the cables are intended. The phases of the production process continue with the REUNITING of all the insulated cables divided by type, section and color. Finally, at the end of the production process, the EXTRUSION of the outer sheath of the cables is carried out, an antechamber for the realization of the finished product, that is, skeins, reels and reels of various sizes.

The finished product is intended for sale at our distributors located all over the world. It is precisely the relationship with customers that differentiates Pappalardo Cavi from its competitors: dialogue and customer satisfaction represent the true mission for the company, oriented daily to immediate and qualitative response to customer requests, to a constant improvement of standards of products and production processes. This is demonstrated by the complete dedication and collaborative spirit of the sales office and all the operators, accustomed to adapting their skills to the required jobs.